At Knickerbocker Roofing & Paving Co., Inc, we specialize in industrial, commercial and institutional roofing solutions. By leveraging over 130 years of industry experience, highly skilled employees, modern and safe equipment, and a wide range of roofing materials, we accommodate all of our customers’ unique roofing needs. One of our areas of expertise is Liquid Applied Membrane Roofing (LAM).

Liquid membrane roofing is a highly effective roofing solution that creates a durable, lightweight, and waterproof barrier between the interior of a building and exterior environmental conditions. While traditional roofing materials—e.g., Built-Up Roofing (B.U.R.), single-ply, and metal—continue to find application in building and construction applications, Liquid Membrane Roofing has become popular among architects, contractors, and other construction industry professionals.

The following article provides an overview of liquid membrane roofing, outlining what it is, the types available, its key benefits, how it compares to roof coatings, and the services available at Knickerbocker Roofing.

What Is Liquid Membrane Roofing?

Liquid roof membranes consist of a one or two component resin that is applied over reinforcement material (typically polyester or fiberglass felt). This system can be applied over a variety of different substrates (modified bitumen, certain single ply membranes, B.U.R., concrete, or metal). It can be applied with squeegees, rollers, or sprayed. Once it has cured, it becomes seamless, UV-resistant, water-resistant, chemical-resistant, while also accommodating movement. Liquid membranes are also aesthetically pleasing, as they can come in a variety of colors.

The technology for the resin-based liquid-applied systems was developed in Europe in the mid-1980s and early 1990s. In the early 2000s, European standards were developed as the popularity of the liquid membranes was making in-roads in the roofing industry and more manufacturers were developing their systems and offering long-term warranties. When these membranes were first introduced in the United States, the drawbacks for these systems were that they were expensive, limited in supply, and extremely difficult to work with. As manufacturers began building factories in the United States, prices dropped significantly and supply became sufficient and as more contractors worked with the systems, labor prices began to drop.

Types of Liquid Membrane Roof Systems

The three types of liquid membrane systems that are the most prevalent in our market are polymethylmethacylate (PMMA), polyurethane, and silicone. These systems are all seamless, meaning that the reinforcement fabric is embedded into the liquid and chemically bonded to the adjacent membrane. The fact that the membrane can flow around any penetration leads to better flashing details than any other roofing systems. These systems all offer long manufacturer warranties up to 30 years.

PMMA

One of the most durable of all liquid membranes, these systems cure quickly and efficiently. With the use of catalysts, inhibitors and separate grades (summer or winter), can be applied in a wide range of temperatures. Another advantage of PMMA liquid applied membranes is that their chemical bonds allow repairs to be easily made years later if needed. Some of the manufacturers have low VOC content so it can be used in enclosed areas (e.g., indoor fountains). These systems do have a limited “pot life”, so there a higher waste factor. Typical application is with squeegees and rollers which corresponds to higher labor costs.

Polyurethane

Polyurethane liquid membranes share many of the same advantages as PMMA products, including fast cure time and relative ease of patching. The main difference between PMMA and polyurethane-based systems are the number of components. There are multi-component polyurethanes and single-component polyurethanes. Multi-component polyurethanes have a faster cure time but a shorter pot life. Single-component polyurethanes have a longer cure time, but they do not have a pot life so there is less waste. Both systems can be applied with squeegee, roller, or sprayed with a special sprayer. Application via sprayer allows for a faster rate of installation, which in turn lowers labor cost. The disadvantage of Polyurethanes is that the system has temperature limitations for application (typically between 40-50 degrees and rising), so planning and scheduling of installation is key.

Silicone

Silicone-based liquid roof systems, in contrast to other liquid roof systems, can be applied without the use of a primer to the substrate in most instances. They are also applied via squeegee, roller, or sprayer. Silicone exhibits a high level of dimensional stability, and extreme temperature fluctuations. It has most of the same advantages as PMMA and Polyurethane systems, but has a greater odor that could potentially limit its applications in sensitive areas/environments (e.g., hospitals and schools).

Benefits of Liquid Membrane Roofing

Benefits of Liquid Membrane Roofing

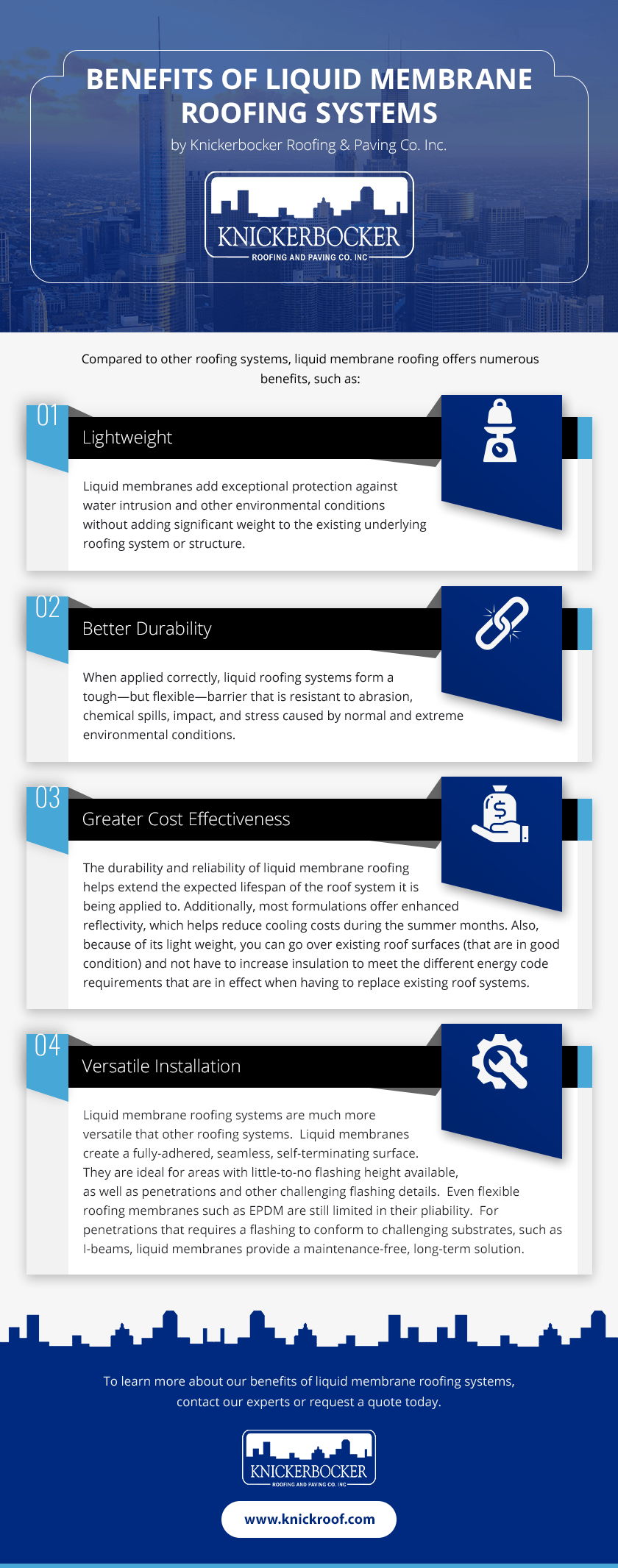

Compared to other roofing systems, liquid membrane roofing offers numerous benefits, such as:

- Lightweight: Liquid membranes add exceptional protection against water intrusion and other environmental conditions without adding significant weight to the existing underlying roofing system or structure.

- Better Durability: When applied correctly, liquid roofing systems form a tough—but flexible—barrier that is resistant to abrasion, chemical spills, impact, and stress caused by normal and extreme environmental conditions.

- Greater Cost Effectiveness: The durability and reliability of liquid membrane roofing helps extend the expected lifespan of the roof system it is being applied to. Additionally, most formulations offer enhanced reflectivity, which helps reduce cooling costs during the summer months. Also, because of its light weight, you can go over existing roof surfaces (that are in good condition) and not have to increase insulation to meet the different energy code requirements that are in effect when having to replace existing roof systems.

- Safer and easier installation: Liquid membrane roofing systems are much safer to install than other roofing systems. For example, bitumen must be heated to higher temperatures in a kettle before it turns into a liquid, which then allows the bitumen to be spread in place. This not only creates a strong odor, but also increases the chance of kettle fires or possible burns to the employees. The use of roof torches in the application of modified bitumen membrane has caused building fires. The application of the liquid membrane by contrast does not need to be heated, and with the low VOC, creates little odor.

Liquid Roof Membranes vs. Liquid Roof Coatings

When speaking about roofing, the terms liquid membranes and liquid coatings are often used interchangeably. While there are some similarities between the two products, there are a few key distinctions.

Liquid Roof Coatings

Applied to the roofing surface to form a moderate protective layer against environmental conditions, namely U.V. protection/reflectivity. These coating have no waterproofing properties, are applied at a much thinner application rate than liquid membranes, and do not have any type of manufacturer’s warranty against water intrusion. If water ponding occurs, many coatings typically flake up and expose the underlying waterproofing.

Liquid Roof Membrane

Liquid membranes are a waterproofing system that is applied at a much thicker application rate than roof coatings, and form a durable and reliable protective barrier that can be covered by a long-term manufacturer’s warranty against water intrusion.

Liquid Membrane Roofing Services by Knickerbocker Roofing

At Knickerbocker Roofing & Paving, we pride ourselves on providing superior quality roofing solutions to customers with residential, commercial, and industrial buildings. Our expert team has the knowledge and expertise necessary to help customers find the right design, material and installation method for their needs.

For customers looking for a liquid roofing system, we offer the ability and expertise to install an extensive selection of liquid membranes and liquid coatings to meet a wide range of functional and aesthetic requirements. For example, we applied thousands of feet of liquid membrane to the roof system of a multi-level residential facility with a unique serpentine design.

Whether you need a new roof system or a protective membrane for an existing roof system we can provide you with the appropriate roofing solution. To learn more about our liquid membrane roofing capabilities, contact our experts or request a quote today.