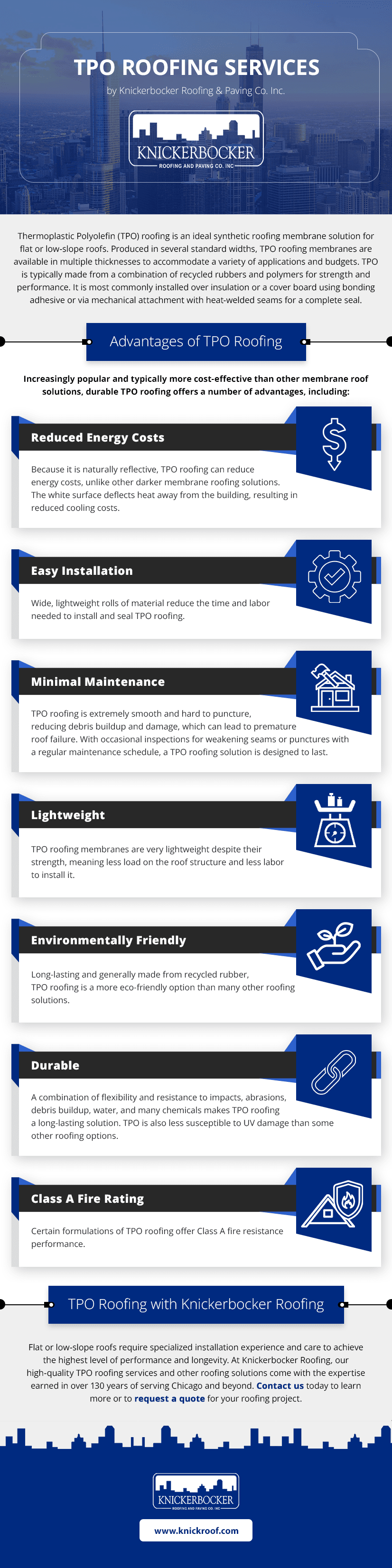

Thermoplastic Polyolefin (TPO) roofing is an ideal synthetic, membrane roofing solution for flat or low-slope roofs. Produced in several standard widths, TPO roofing membranes are available in multiple thicknesses to accommodate a variety of applications and budgets. TPO is typically made from a combination of recycled rubber with some added fillers for strength and performance and is applied as a single-ply layer over insulation with heat-welded seams for a complete seal.

Advantages of TPO Roofing

Increasingly popular, and typically more cost-effective than other membrane roof solutions, durable TPO roofing offers a number of advantages, including:

- Reduced Energy Costs: Because it’s naturally reflective, TPO roofing can reduce energy costs, unlike other darker membrane roofing solutions. The white surface deflects heat away from the building, resulting in reduced cooling costs.

- Flexible Insulation Options: Multiple choices for insulation materials mean solutions to fit your budget and meet your energy efficiency and R-value requirements.

- Easy Installation: Wide, lightweight rolls of material reduce the time and labor needed to install and seal TPO roofing.

- Minimal Maintenance: TPO roofing is extremely smooth and hard to puncture, reducing debris buildup and damage which can lead to premature roof failure. With occasional inspections for weakening seams or punctures with a regular maintenance schedule, a TPO roofing solution is designed to last.

- Lightweight: TPO roofing membranes are very lightweight despite their strength, meaning less load on the roof structure and less labor to install it.

- Environmentally Friendly: Long-lasting and generally made from recycled rubber, TPO roofing is a more eco-friendly option than many other roofing solutions.

- Durable: A combination of flexibility and resistance to impacts, abrasions, debris buildup, water, and many chemicals makes TPO roofing a long-lasting solution. TPO is also less susceptible to UV damage than some other roofing options.

- Class A Fire Rating: Certain formulations of TPO roofing offer Class A fire resistance performance.

Roofing Installation Process

TPO roof installation is a fairly straightforward process, but as with most roofing projects, solid preparation is important to ensure a roof that performs well. A TPO roof consists of three basic layers: insulation, optional cover boards, and the TPO membrane.

Insulation

Insulation, naturally, plays a very significant role in roof performance, not only in controlling temperature but also by providing a solid layer onto which the roofing can be installed when no cover board is needed. Standard insulation options are:

- Polyisocyanurate (Polyiso) – Polyiso offers one of the higher R-values among commonly used roofing insulation, where an extended reduction in energy costs will greatly offset a slightly higher initial cost.

- Extruded Polystyrene (XPS) – XPS is a dense, lightweight foam material with solid R-values and mid-range pricing.

- Expanded Polystyrene (EPS) – Similar to XPS, EPS insulation has a slightly lower R-value, but is more permeable than XPS, allowing indoor moisture and humidity to dissipate more easily.

Cover Boards

When XPS or EPS insulation is used, most manufacturers recommend a thin cover board be installed between the insulation and the TPO membrane for added stability and protection. Polyiso insulation generally does not require cover boards, and in fact, polyiso is a common cover board material, along with gypsum and cement.

TPO Membrane

Finally, the sheets of TPO membrane are installed using a ballast system or fastening (adhesive or mechanical) to attach it to your building.

- Fasteners – A system of screws and plates mechanically attach the membrane to the substrate.

- Adhesive – Glue or another adhesive holds the roof membrane to the substrate.

- Ballast system – This less common method uses weights, typically a layer of gravel, to keep the roof membrane in place.

Roof seams are permanently bonded using hot-air guns to weld the layers together, creating an air-tight seal. Some ballasted systems are a seamless installation, while others typically use seam tape.

TPO Roofing with Knickerbocker Roofing

Flat or low-slope roofs require specialized installation experience and care to achieve the highest level of performance and longevity. At Knickerbocker Roofing, our high-quality TPO roofing services and other roofing solutions come with the expertise earned in over 130 years of serving Chicago and beyond. Contact us today to learn more or to request a quote for your roofing project.