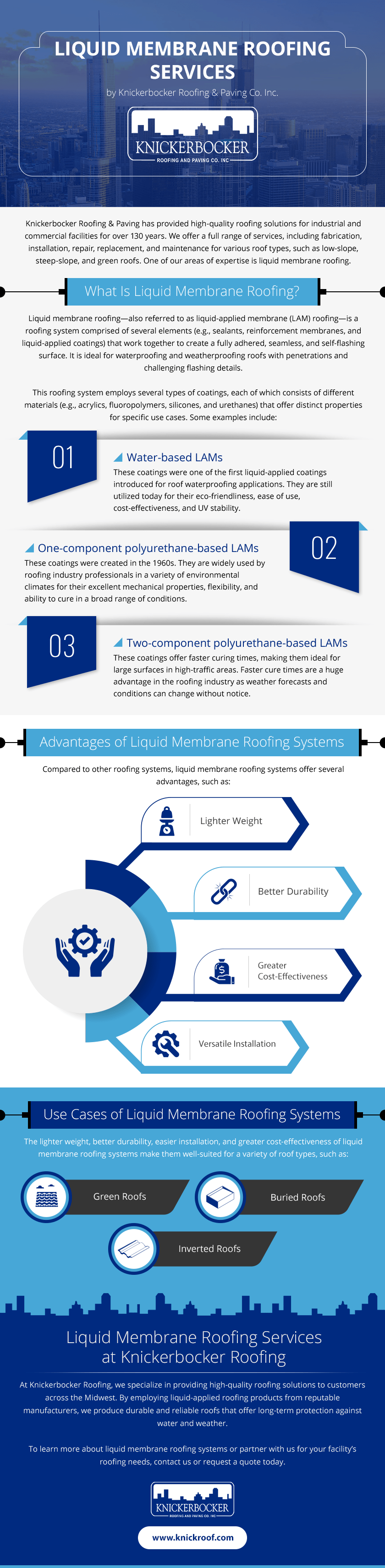

What Is Liquid Membrane Roofing?

Liquid membrane roofing—also referred to as liquid-applied membrane (LAM) roofing—is a roofing system comprised of several elements (e.g., sealants, reinforcement membranes, and liquid-applied coatings) that work together to create a fully adhered, seamless, and self-flashing surface. It is ideal for waterproofing and weatherproofing roofs with penetrations and challenging flashing details.

This roofing system employs several types of coatings, each of which consists of different materials (e.g., acrylics, fluoropolymers, silicones, and urethanes) that offer distinct properties for specific use cases. Some examples include:

Water-based LAMs

These coatings were one of the first liquid-applied coatings introduced for roof waterproofing applications. They are still utilized today for their eco-friendliness, ease of use, cost-effectiveness, and UV stability.

One-component polyurethane-based LAMs

These coatings were created in the 1960s. They are widely used by roofing industry professionals in a variety of environmental climates for their excellent mechanical properties, flexibility, and ability to cure in a broad range of conditions.

Two-component polyurethane-based LAMs

These coatings offer faster curing times, making them ideal for large surfaces in high-traffic areas. Faster cure times are a huge advantage in the roofing industry as weather forecasts and conditions can change without notice.

Advantages of Liquid Membrane Roofing Systems

Compared to other roofing systems, liquid membrane roofing systems offer several advantages, such as:

- Lighter weight. The application of sealant, reinforcement, and coating has minimal effect on the total weight of the structure, allowing it to maintain its original structural integrity.

- Better durability. The roofing system provides a fully bonded and seamless barrier between the building and external water and weather conditions, protecting and preserving the internal structure. The complete system, when installed and maintained correctly, can last up to and exceed 25 years.

- Safer and easier installation. The liquid state of the coating material allows for fast, safe, and easy application on various roofing materials (e.g., asphalt, bitumen, and concrete) in and around roof structures.

- Greater cost-effectiveness. Liquid membrane roofing systems protect roofs, which reduces the risk of the building needing roof repairs or replacement. Additionally, depending on the formulation of the coating employed, they can reflectivity, which helps lower cooling costs during summer months. LAM roofs can also provide added durability when installed over an existing roof system that has been properly maintained.

Use Cases of Liquid Membrane Roofing Systems

The lighter weight, better durability, easier installation, and greater cost-effectiveness of liquid membrane roofing systems make them well-suited for a variety of roof types, such as:

Green roofs

Green roofs often require some form of irrigation system to maintain the vegetation. Liquid membrane roofing systems easily accommodate the roof penetrations and protrusions required for irrigation, providing waterproofing without interfering with the roof’s function.

Buried roofs

Buried roofs are typically part of some underground structures (e.g., car parking decks). They must have highly durable waterproofing systems since any repair or replacement operation would significantly affect the ability to use them. Liquid membrane roofing systems provide a long-term waterproofing solution that prevents water intrusion across a wide range of temperatures and other environmental conditions.

Inverted roofs

Inverted roofs are roofs where the waterproofing layer is beneath—instead of above—the insulation layer. Liquid membrane roofing systems are ideal for this roof type as they provide a seamless waterproofing layer.

Liquid Membrane Roofing Services at Knickerbocker Roofing

As indicated above, liquid membrane roofing systems are suitable for use on a wide range of roofs. They provide a lightweight, easy-to-apply, and durable waterproofing barrier that protects buildings from water intrusion damage and degradation. If you’re looking for a roofing service provider to install a liquid membrane roofing system on your facility, turn to the experts at Knickerbocker Roofing.

At Knickerbocker Roofing, we specialize in providing high-quality roofing solutions to customers across the Midwest. By employing liquid-applied roofing products from reputable manufacturers, we produce durable and reliable roofs that offer long-term protection against water and weather.

To learn more about liquid membrane roofing systems or partner with us for your facility’s roofing needs, contact us or request a quote today.