Ethylene propylene diene monomer (EPDM) is a highly durable synthetic terpolymer rubber made from a mixture of sawdust, slate dust, and recycled tires. This material, which is available in either black or white, is an excellent choice for use in a roofing system. EPDM roofing can be used on flat roofs and is frequently referred to as rubber roofing or rubber membrane roofing.

EPDM terpolymer is incredibly economical and versatile, as it costs approximately $0.80 per square foot. EPDM roofing is typically cut in widths of up to 50 feet, lengths up to 200 feet, and up to 90 mm in thickness.

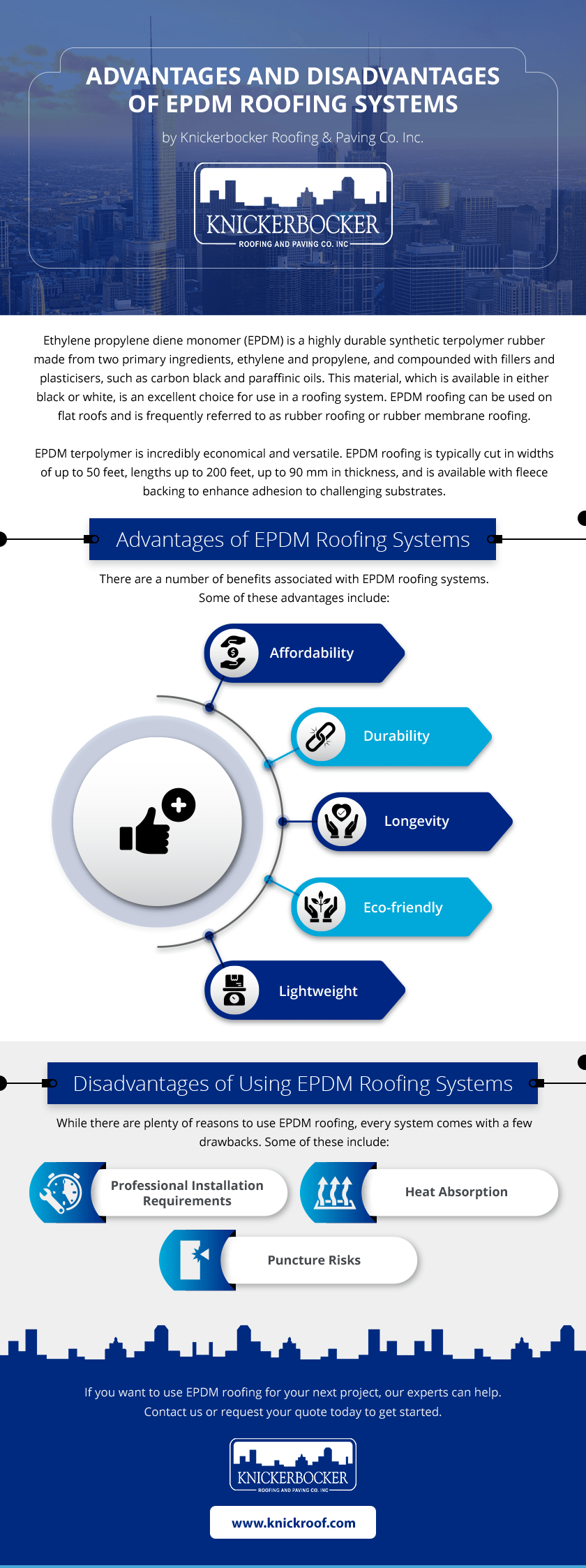

Advantages of EPDM Roofing Systems

There are a number of benefits associated with EPDM roofing systems. Some of these advantages include:

- Affordability. EPDM offers an incredibly cost-effective solution—EPDM is one of the cheapest flat roofing materials on the market. The price of installation is also cheaper than many alternatives, as EPDM roofing systems are quick and easy to set up.

- Durability. EPDM roofing systems are highly durable. The material doesn’t scratch easily and will hold up under exposure to UV rays, wind, extreme temperatures, hail, rain, and will tolerate limited exposure to fire.

- Longevity. With proper care, EPDM can last for up to 30 years Leaks and tears can be easily repaired.

- Eco-friendly. EPDM used in roofing solutions is fabricated from unused waste materials, which means that EPDM roofing systems are very eco-friendly.

- Lightweight. EPDM roofing materials are incredibly lightweight compared to many other solutions.

Disadvantages of Using EPDM Roofing Systems

While there are plenty of reasons to use EPDM roofing, every system comes with a few drawbacks. Some of these include:

- Professional installation requirements. This type of roofing system requires trained and certified professionals to seal the roof, meaning that business owners cannot install EPDM roofing themselves.

- Heat absorption. The black rubber itself absorbs a great deal of heat, and white EPDM rubber is more expensive.

- Puncture risks. This type of material can be punctured more easily than some comparable roofing solutions, although it is very easy to patch and repair.

What is the Installation Process for EPDM Roofing Systems?

Although they must be installed by professionals, the process of installing EPDM roofing systems is fairly straightforward. They can either be adhered with a liquid adhesive, ballasted, or mechanically fastened. Liquid adhesive offers the longest lasting adhesion, but takes the longest to complete. Many new construction installations are ballasted with river rock and/or concrete pavers.

Who Uses EPDM Roofing?

It is most common to use EPDM roofing systems on commercial or industrial buildings with either flat or low sloped roofs. While homeowners can certainly use these systems in residential neighborhoods, the low aesthetic appeal often drives residential projects to choose other methods. While EPDM roofing is not typically utilized in single residential family housing, it is more common in townhouses, apartments, and condominiums.

Some of the most common industrial and commercial buildings that utilize EPDM roofing systems include:

- Hotels

- Shopping centers

- Warehouses

- Hospitals

- Schools

- Car dealerships

- Large retail stores

- Office buildings

Work With Knickerbocker Roofing

EPDM roofing systems provide an affordable, durable, and eco-friendly option for flat or low sloped roofs. Utilizing a highly trained team to install your roofing further increases these benefits, ensuring that it will last for decades to come.

If you want to use EPDM roofing for your next project, our experts can help. Contact us or request your quote today to get started.