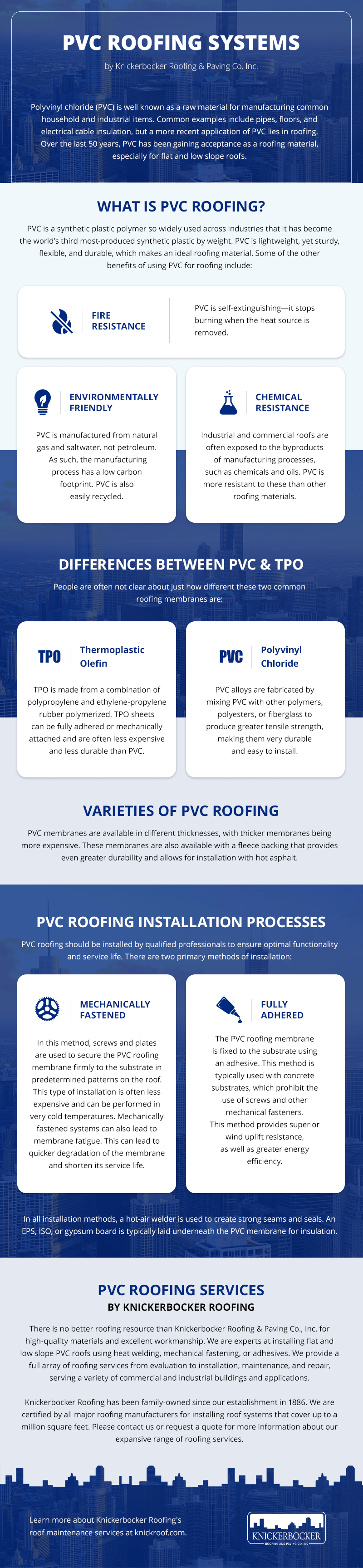

Polyvinyl chloride (PVC) is well known as a raw material for manufacturing common household and industrial items. Common examples include pipes, floors, and electrical cable insulation, but a more recent application of PVC lies in roofing. Over the last 50 years, PVC has been gaining acceptance as a roofing material, especially for flat and low slope roofs.

What is PVC Roofing?

PVC is a synthetic plastic polymer so widely used across industries that it has become the world’s third most-produced synthetic plastic by weight. PVC is lightweight, yet sturdy, flexible, and durable, which makes an ideal roofing material. Some of the other benefits of using PVC for roofing include:

- Fire resistance. PVC is self-extinguishing—it stops burning when the heat source is removed.

- Environmentally friendly. PVC is manufactured from natural gas and saltwater, not petroleum. As such, the manufacturing process has a low carbon footprint. PVC is also easily recycled.

- Chemical resistance. Industrial and commercial roofs are often exposed to the byproducts of manufacturing processes, such as chemicals and oils. PVC is more resistant to these than other roofing materials.

Differences Between PVC & TPO

People are often not clear about just how different these two common roofing membranes are:

- Thermoplastic olefin (TPO). TPO is made from a combination of polypropylene and ethylene-propylene rubber polymerized. TPO sheets can be fully adhered or mechanically attached and are often less expensive and less durable than PVC.

- Polyvinyl chloride (PVC). PVC alloys are fabricated by mixing PVC with other polymers, polyesters, or fiberglass to produce greater tensile strength, making them very durable and easy to install.

Varieties of PVC Roofing

PVC membranes are available in different thicknesses, with thicker membranes being more expensive. These membranes are also available with a fleece backing that provides even greater durability and allows for installation with hot asphalt.

PVC Roofing Installation Processes

PVC roofing should be installed by qualified professionals to ensure optimal functionality and service life. There are two primary methods of installation:

- Mechanically fastened. In this method, screws and plates are used to secure the PVC roofing membrane firmly to the substrate in predetermined patterns on the roof. This type of installation is often less expensive and can be performed in very cold temperatures. Mechanically fastened systems can also lead to membrane fatigue. This can lead to quicker degradation of the membrane and shorten its service life.

- Fully adhered. The PVC roofing membrane is fixed to the substrate using an adhesive. This method is typically used with concrete substrates, which prohibit the use of screws and other mechanical fasteners. This method provides superior wind uplift resistance, as well as greater energy efficiency.

In all installation methods, a hot-air welder is used to create strong seams and seals. An EPS, ISO, or gypsum board is typically laid underneath the PVC membrane for insulation.

PVC Roofing Services by Knickerbocker Roofing

There is no better roofing resource than Knickerbocker Roofing & Paving Co., Inc. for high-quality materials and excellent workmanship. We are experts at installing flat and low slope PVC roofs using heat welding, mechanical fastening, or adhesives. We provide a full array of roofing services from evaluation to installation, maintenance, and repair, serving a variety of commercial and industrial buildings and applications.

Knickerbocker Roofing has been family-owned since our establishment in 1886. We are certified by all major roofing manufacturers for installing roof systems that cover up to a million square feet. Please contact us or request a quote for more information about our expansive range of roofing services.