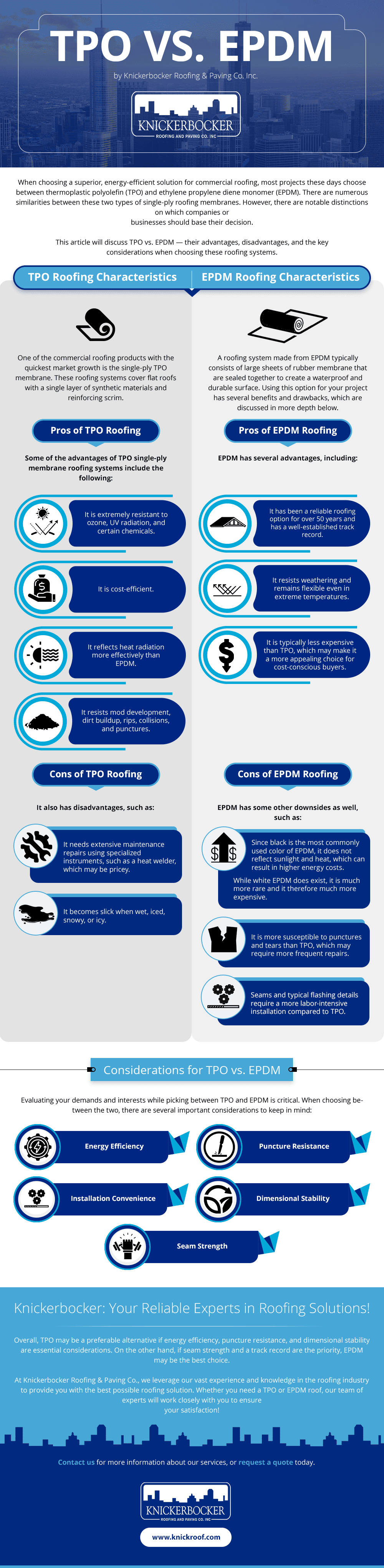

TPO vs. EPDM

When choosing a superior, energy-efficient solution for commercial roofing, most projects these days choose between thermoplastic polyolefin (TPO) and ethylene propylene diene monomer (EPDM). There are numerous similarities between these two types of single-ply roofing membranes. However, there are notable distinctions on which companies or businesses should base their decision.

This article will discuss TPO vs. EPDM — their advantages, disadvantages, and the key considerations when choosing these roofing systems.

TPO Roofing Characteristics

One of the commercial roofing products with the quickest market growth is the single-ply TPO membrane. These roofing systems cover flat roofs with a single layer of synthetic materials and reinforcing scrim.

Pros of TPO Roofing

Some of the advantages of TPO single-ply membrane roofing systems include the following:

- It is extremely resistant to ozone, UV radiation, and certain chemicals.

- It is cost-efficient.

- It reflects heat radiation more effectively than EPDM.

- It resists mod development, dirt buildup, rips, collisions, and punctures.

Cons of TPO Roofing

It also has disadvantages, such as:

- It needs extensive maintenance repairs using specialized instruments, such as a heat welder, which may be pricey.

- It becomes slick when wet, iced, snowy, or icy.

EPDM Roofing Characteristics

A roofing system made from EPDM typically consists of large sheets of rubber membrane that are sealed together to create a waterproof and durable surface. Using this option for your project has several benefits and drawbacks, which are discussed in more depth below.

Pros of EPDM Roofing

EPDM has several advantages, including:

- It has been a reliable roofing option for over 50 years and has a well-established track record.

- It resists weathering and remains flexible even in extreme temperatures.

- It is typically less expensive than TPO, which may make it a more appealing choice for cost-conscious buyers.

Cons of EPDM Roofing

EPDM has some other downsides as well, such as:

- Since black is the most commonly used color of EPDM, it does not reflect sunlight and heat, which can result in higher energy costs.

- While white EPDM does exist, it is much more rare and it therefore much more expensive

- It is more susceptible to punctures and tears than TPO, which may require more frequent repairs.

- It is heavy and requires more labor-intensive installation than TPO sheets.

Considerations for TPO vs. EPDM

Evaluating your demands and interests while picking between TPO and EPDM is critical. When choosing between the two, there are several important considerations to keep in mind:

Energy Efficiency

TPO is a great choice if energy efficiency is a top concern. Its light color reflects sunlight and heat away from the building, reducing energy consumption and cutting down on electricity costs. In contrast, EPDM’s dark color can absorb heat, raising the temperature inside the building and potentially increasing cooling costs.

Puncture Resistance

If the roof will be exposed to heavy foot traffic or other potential sources of damage, TPO is the way to go. It is more durable and resistant to punctures, rips, and other forms of disfigurement than EPDM. Therefore, it can last longer and require fewer repairs.

Installation Convenience

Both options can be installed easily and quickly for those who want to save on installation costs. Both TPO and EPDM can be installed in large, single-ply sheets that are mechanically fastened (TPO), adhered (both), heat welded (TPO), or ballasted (EPDM) which can save time and reduce labor costs.

Dimensional Stability

When it comes to maintaining the appearance and functionality of the roof over time, TPO is the more durable option. It is less prone to shrinking and expanding than EPDM. Therefore, it can better withstand temperature fluctuations and prevent cracks, gaps, and other damage over time.

Seam Strength

EPDM is the better choice for those who prioritize minimizing the risk of leaks. Its strong seams are usually formed with an adhesive or tape, which creates a watertight seal. However, TPO is often heat welded, which can create a stronger connection than glue or tape. If not done properly, it can lead to weaker seams than EPDM.

Knickerbocker: Your Reliable Experts in Roofing Solutions!

Overall, TPO may be a preferable alternative if energy efficiency, puncture resistance, and dimensional stability are essential considerations. On the other hand, if seam strength and a track record are the priority, EPDM may be the best choice.

At Knickerbocker Roofing & Paving Co., we leverage our vast experience and knowledge in the roofing industry to provide you with the best possible roofing solution. Whether you need a TPO or EPDM roof, our team of experts will work closely with you to ensure your satisfaction!

Contact us for more information about our services, or request a quote today.